NigelK

Member

| Joined: | 07-16-2014 |

| Location: | |

| Posts: | 200 |

| Status: |

Offline

|

|

Dear All

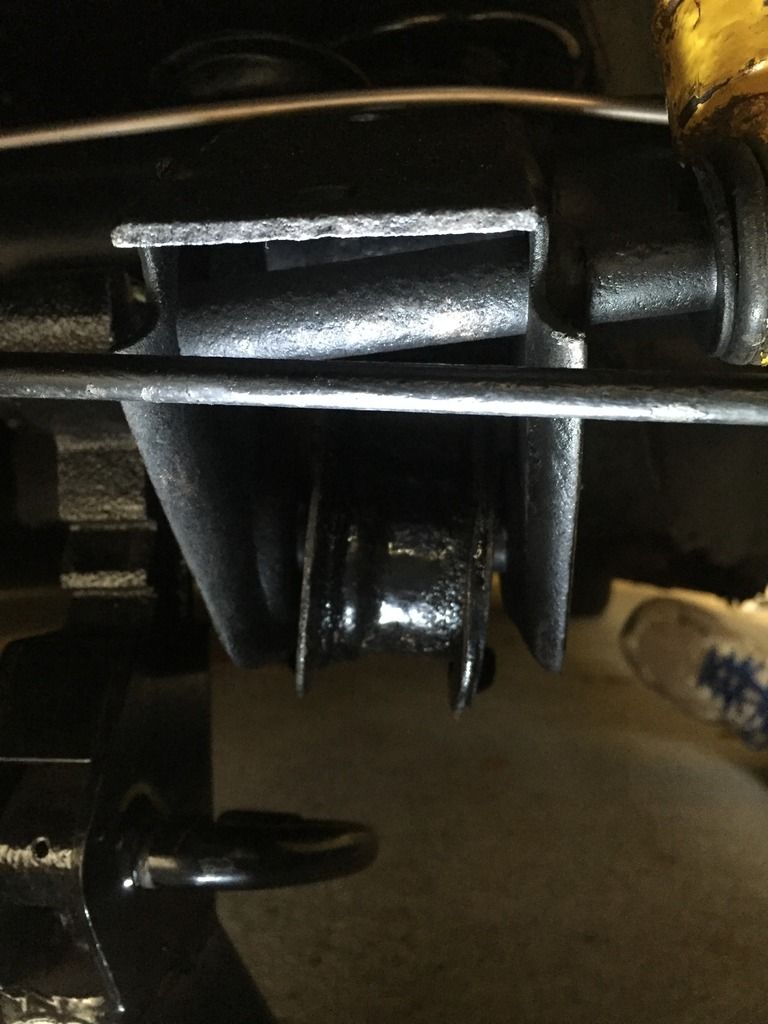

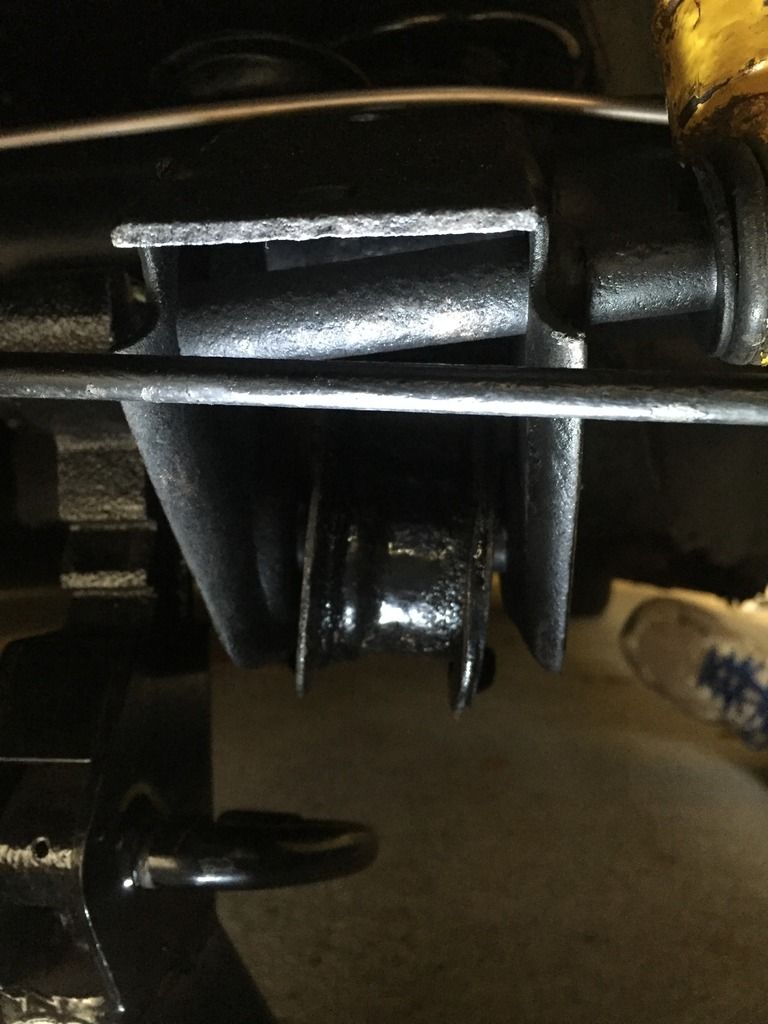

My GT still leans to one side, about 2cm lower on the right-hand (driver's) side at both the front and rear wheel arches. I've already done all the usually recommended fixes - replaced suspension bushings, tightened bolts with load on the suspension, replaced front and rear coil springs and shock absorbers. When the LSD axle was fitted a few months back, LotusBits reported that the rear lower trailing arm metalastik bushings on the right-hand side were toast, despite being less than 2 years old. There is a noticeable twist in the right-hand side lower trailing arm relative to the axle flanges, which is resulting in the bushing crush tube tearing out of the surrounding rubber. This is shown in the picture below.

The twist of the lower trailing arm seems to be caused by misalignment of the trailing arm mounting holes in the chassis rail, which are at least 1 cm out of alignment inboard to outboard. The picture below shows there has been some fairly significant welding repair to this part of the chassis rail. Incidentally, this is the same chassis rail to which attention was required to the front sub-frame mounting holes, which were also out of alignment inboard to outboard, and incorrectly positioned in the chassis rail itself. This is making me think that a PO did a lot of welding on this chassis rail, but did not re-drill the suspension mounting holes correctly.

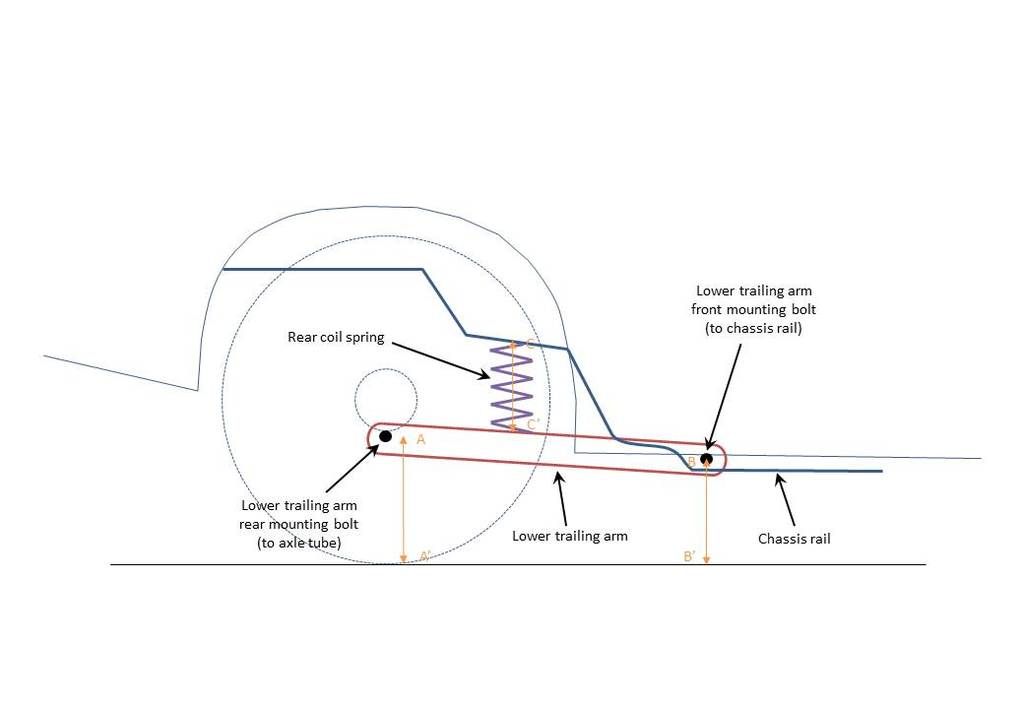

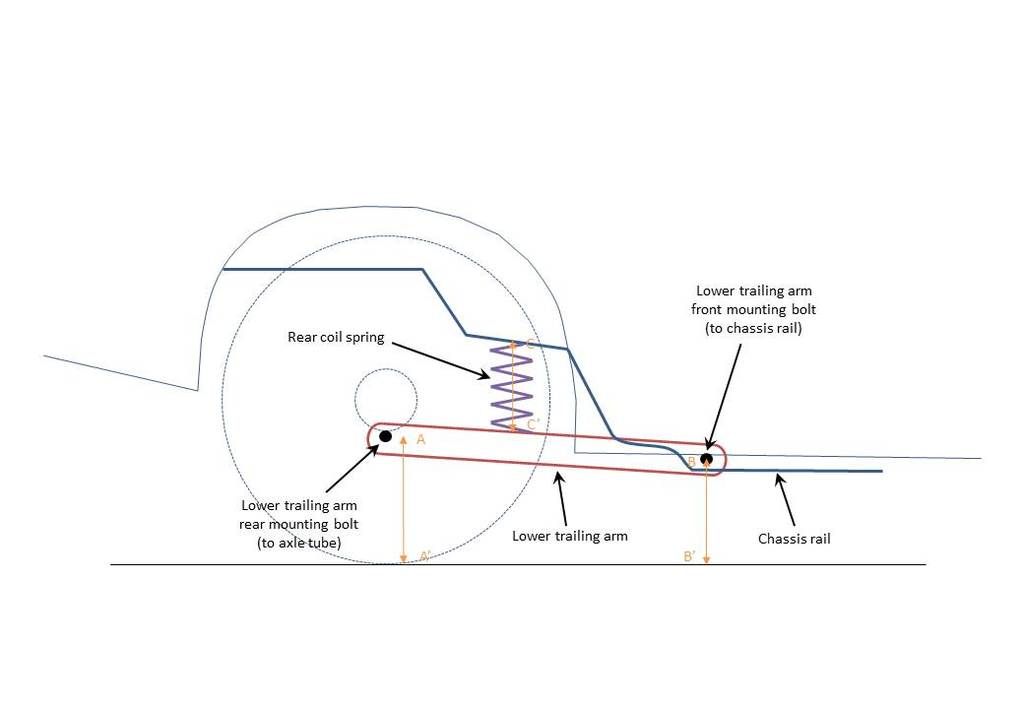

It is possible, therefore, that the lean is also attributable to incorrect positioning of the lower trailing arm mounting holes, which are not only misaligned inboard to outboard in the chassis rail but also incorrectly positioned in the chassis rail itself (i.e. just like the mounting holes for the front sub-frame). Remedying the inboard-outboard misalignment should be relatively straightforward. But given the substantial amount of welding all along the chassis rail, how best to reposition the mounting holes relative to the chassis rail? I have drawn a schematic below, which is hopefully clear.

The question is, which direction should the lower trailing arm mounting holes move in the chassis rail, in order to increase the dimension B-B' (and therefore raise the chassis/body on the driver's side, correcting the lean)? The dimension A-A' should be fixed, as it is set by the axle flanges which are fixed relative to the wheel and therefore the ground (assuming constant tyre pressure). My current thinking is that moving the mounting holes down relative to the chassis rail will allow the rear coil spring to expand, lengthening the dimension C-C', and raising the chassis/body. Conversely, moving the mounting holes up relative to the chassis rail will compress the rear coil spring, shortening the dimension C-C', and lowering the chassis/body. Does this sound right?

Many thanks in advance for any thoughts / advice.

Best wishes,

NigelLast edited on 08-15-2017 08:44 pm by NigelK

|