| Moderated by: Greg Fletcher | ||

| Author | Post | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

|

answerman Member

|

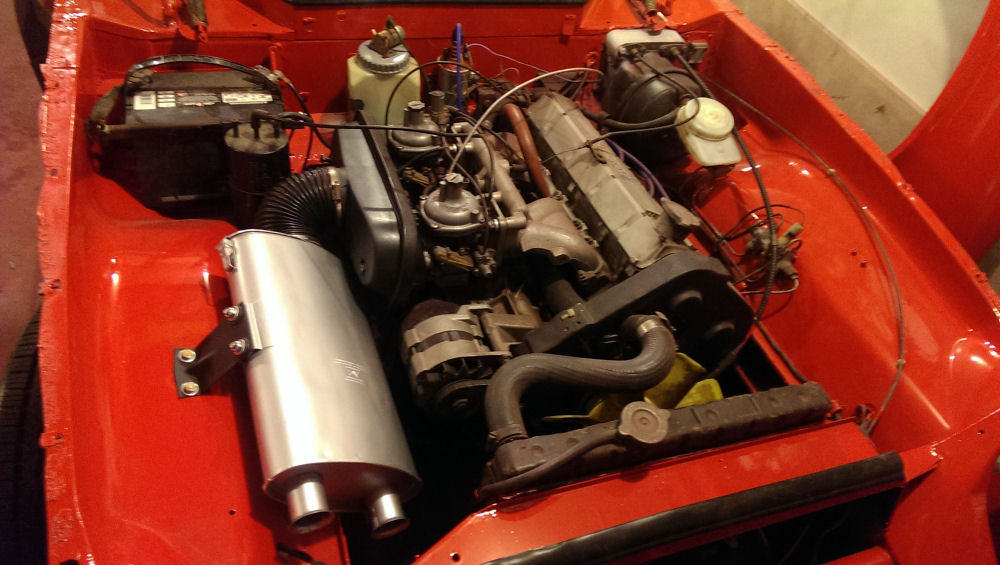

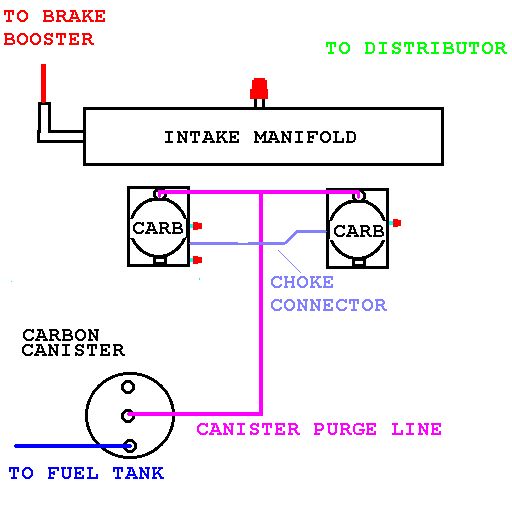

Well, I've owned 16173 for about 4 days now, and driven her around town for a couple of hours total. That ended today because I need to really take a good look at the brakes before she hits the road again. Here's what I've learned so far. First the general description and details about the car itself: 1974 JH MkII, seems to run pretty well though she idles very rough. Not too worried about that yet. Included with the purchase was the original owners manual complete with foldout wiring diagram (which proved invaluable 24 hours later, as explained in the next paragraph), a shop manual, a Haynes manual for the Strombergs, the original (I think anyway) hardtop which is in pretty good shape except for the fact that someone decided it was a good idea to paint it metallic grey, and all the receipts for the work that the previous two owners had done going back to 2001. Interior is really nice, probably not original. Body is ok... it's been repainted (red) and mostly solid except for the rails being a little soft and a few soft spots in the floor. That'll be the winter project. Now, on the way home I noticed that it wasn't charging... meter wasn't moving, but the ignition light wasn't coming on either. Battery seems to be good (thankfully) and after doing a voltage test across the battery I determined that it was not charging at all. So, I charged up the battery and spent Sunday afternoon between the manual, the car, and this site learning how the LUA604 was supposed to work. The receipts showed it was replaced in 2009 so I was hopeful it was something simple. Diving into it, and scratching my head repeatedly, I figured out that whoever installed the alternator didn't seem to understand it. Long story short... I pulled out the wiring they had spliced in (with spin on wire nuts, can you believe it?) and basically replaced the three wires with new ones, with new connectors, and actually connected the wires where they were supposed to be connected (the brown/yellow exciter wire was connected to one of the 3/8" terminals, and the lighter brown wire wasn't even connected). Put it back together, crossed my fingers, fired her up, and watched the voltmeter rise up to a little over 14V. Whew. So, that solved, my next step was going to be to investigate why the tach and temp gauge don't work. Looking at the wiring diagram, I wonder if it's just a bad connection since if I remember right they share a white wire from the ignition switch. Meanwhile, I took it out a bit the past two days to play with it a little. I had noticed the car pulled to the left a bit and could hear the pads dragging a bit, so it was no surprise when, today, I hit the brakes and the left front wheel pretty much locked up. Didn't skid but it was pretty tight. So, it gingerly went back home and into the garage, where it will sit while I ponder just how much of the braking system I want to replace. I'll update as things progress. Thanks so much to Greg and this for being such a resource to me... the last time I tackled a project car (1975 Fiat X1/9) was back in the late 80's when we didn't have this Internet thing. It's great to have so many knowledgable people here to draw from. Attachment: JH16173-1-800.jpg (Downloaded 1052 times) |

|||||||||

|

answerman Member

|

Long as I'm posting pictures.... here's another angle. Interior, as I said, looks way too good to me to be original. Attachment: JH16173-2-800.jpg (Downloaded 1056 times) |

|||||||||

|

Jensen Healey Super Moderator

|

Welcome Answerman, Looks like you're in for some new brake hoses at the very least! Have fun, Kurt Housh San Anselmo, Ca JH 13148 |

|||||||||

|

Art DeKneef Member

|

Welcome to the group. Good job on the alternator. Checking and cleaning any suspect connections will be a good idea. I wouldn't drive the car until you are sure on the age and condition of the timing belt. If the records show it is more than a few years old you should consider replacing it. Cheap insurance. The brakes probably need a good cleaning and overhaul. Also replace the rubber brake lines with the steel ones. That usually fixes braking issues. Unless the rotors are warped or the calipers are rusted. If you search the site you'll find a couple of threads on checking out a car if it has sat for a while and fixing the brakes. Art |

|||||||||

|

answerman Member

|

Thanks for the advice, Art. The receipts show that the timing belt was replaced about 3 years / 6000 miles ago. That's on my list... it looks ok but I'm not sure how the car was stored/used during that time. This weekend I'll be pulling the calipers off and seeing just how stuck the left front is. At this point I'm pretty much prepared to replace the calipers, pads, and brake lines assuming that the caliper is indeed sticking. If not, maybe I can get away with just the pads and lines for now. The rotors, from what I can see looking through the wheel, don't seem to be too bad so I'm hoping that maybe I can hold off on them. Hoping I can get the brakes resolved shortly to at least get me through a couple of months (it'll be winter here soon and she's definitely not going out in the snow, I have a Ford Excursion for that!). To give me a bit of incentive, our town has an Octoberfest downtown festival the last weekend in September (go figure) and they do an informal car show on Friday night, just everyone parking on the main drag. Every year they do a featured "theme" and of course this year, ironically, is "British Sports Cars". So of course I want to get her down there, even though she's not near show ready. We'll see if it happens. |

|||||||||

|

Art DeKneef Member

|

If the calipers aren't too bad you might be able to rebuild them instead of buying new ones. It's not that difficult of a job. The pistons are what is probably stuck on the left side. The hard part is getting the pistons out. After that, inspecting them and cleaning with replacing the gaskets should fix it. Isn't that the way it always is. Something comes up and the car is down. Hey you still have 2 weeks to go. |

|||||||||

|

answerman Member

|

Small victories... did some more wire tracing last night and found that the reason the temp gauge wasn't working was because the wire that was supposed to be connected to the sensor was lying down under the carbs. Popped it back on the spade and it works fine. Wish they were all this easy. Still no tach though. It doesn't move at all. Am I correct in assuming that if the white/slate wire from the tach to the ballast resistor isn't connected, the car won't run? I could just disconnect it and try, I guess, but since I'm here... |

|||||||||

|

subwoofer Member

|

Are you sure some DPO hasn't jumped the coil+ wire from another circuit? The tach will only work if it is connected in series with the coil. I had this "fix" in Ms. Jensen when I bought her, the tach came and went as the fuse box misbehaved in the usual way. -- Joachim |

|||||||||

|

answerman Member

|

Haven't touched 16173 since last week, as I needed to fix up her room. Funny... I was reading through Joachim's story of his Ms. Jensen and it's oddly paralleling mine. Spent the weekend finishing up the insulating and drywalling of the garage (I had done the ceiling a couple of weeks ago, and I just needed to do the walls to finish). Now that that's done, I can get back to her. Bonus find of the weekend, and perfect timing... wifey wanted to go out rummage saling on Saturday, and the first place we stopped had a 4000W flush wall mount electric heater. $15 bucks, and it's never been used. That went into the wall before the insulation and drywall went up. Now I'm really ready for winter. |

|||||||||

|

answerman Member

|

Well, did the experiment I talked about. Started her up, ran her for a bit, then shut her down and pulled the wire off the ballast resistor (the one that runs to the tach). Tried starting her again... she would catch once like she wanted to start and then die. So, that tells me initially that the 12v is going through the tach as it should. Or if it's jumped, it's not under the hood anyway. Garage will be cleaned and ready tomorrow... then I can start in earnest. |

|||||||||

|

answerman Member

|

The project inches along. Being in Wisconsin, I've got maybe a month at best of driving weather before winter gets here, so I set my goal of getting Ms. Jenavieve drivable for the short term (yes, she got a name). Talked with Greg and he didn't have any calipers on the shelf, so I found a cheap Cardone rebuild caliper to get me through for now (it's actually specced for a Spitfire but supposedly it's a direct replacement, sure looks like the same one). I did order new brake hoses from Greg since he had those in stock. Assuming that all's well there once I get these parts in, I'll spend the next few weeks getting a little driving enjoyment and once winter comes, she will go into full restore mode. At that time, I'll probably pull both calipers and send them to Greg to have them rebuilt. I'll get there. Oh... and I *finally* figured out, after reading the manual, searching the forum, and looking at pictures... how to properly stow the soft top. It actually works pretty well if you do it exactly right. It almost looks like the picture in the owners manual, though my top is a little stiff so the "flaps" at the rear quarters don't compress down quite tight enough to roll up super tight... but they do fit and I've got the cover nicely installed over the top. The trick, the part I had the hardest time understanding, is to drop the rear rail down behind the frame before rolling the top. You wouldn't think it would be that complicated. |

|||||||||

|

answerman Member

|

Well, this is interesting. I'll be looking more into this tomorrow when I have more time, but the caliper replacement went way better than I expected... until the end. Old caliper came right off. I was expecting to have to do a lot more persuasion on the mounting bolts and brake line nut than I had to. Everything loosened up nicely. Oh, and the caliper is seriously locked up. Couldn't move the pistons at all, at least by hand. Assembled the new pads in the new caliper, and slid it into place. Holding it in place, there was just a little clearance between the pads and the rotor... perfect! My troubles are solved, right? Well, not so fast. I inserted the bolts and tightened them finger tight... and the rotor wouldn't turn. Scratched my head over this for a bit... checked the pads, not dragging. In fact they were rattling around a bit. Looked further into it and the outside edge of the caliper is tight against the rotor. Huh? So I looked at it from the front, and I see that the rotor is not even close to being centered in the caliper. Well, that's no good. Took it apart and put it together a couple of times, just to be sure I had it right (sheesh, it's not that complicated) but all with the same result. So, tomorrow I do a little more playing with it. Thinking about it, it's not an issue with adding spacers to the caliper bolts because that will make it worse... it needs to move in the other direction, and obviously it can't because it's already tight against the mounting surface. Or, the rotor needs to move inward...? Wondering if maybe it's not a stock rotor? Too thick maybe? I'd guess it at about 3/8" which from what I've seen in other posts sounds about right. Or maybe the mounting surface (didn't peek back there) is bent somehow? I'll be taking some very careful measurements tomorrow to investigate if there are any differences between the two calipers that would cause this, but I would guess that there is about 1/4" of clearance between the caliper frame on the inside edge, and none at all (tight against the rotor) on the outside edge. Really confused. More info after sleeping on it and looking at it again. Last edited on 09-30-2012 05:55 am by answerman |

|||||||||

|

answerman Member

|

OK, things are making more sense today. Turns out that the Spitfire caliper is not exactly the same. The mounting lugs are about 1/4" closer to the caliper body than they were on the Jensen caliper. So, what was actually hanging up was the edge of the rotor. Not to be dissuaded, I decided to disassemble the old caliper. After struggling with getting the pistons removed (compressed air works great to remove one, but then I had to figure out a way to seal the side I removed so that I could remove the other one) I took a good look at the inside of the old caliper, and it's basically more dirty than anything else. So, I took some emery cloth and shined things up, and the inside of the caliper looks great now. The pistons look almost as good, and they all slide together nice and smooth. Thinking maybe what I will do tomorrow is disassemble the Spitfire caliper and swipe the seals and maybe the pistons to rebuild my old caliper myself, since I went this far. |

|||||||||

|

answerman Member

|

Worked like a charm. Reassembled the old caliper body with the removables from the new one. Ms. Jenavieve is drivable again. Drove around for about an hour today just because I could. She is still pulling a bit when I brake, but not nearly as bad. I figure my hoses from Greg should be arriving probably Tuesday, and when I get them I will probably disassemble and clean the other caliper and replace the pads on that side, since I have them. Having fun again. |

|||||||||

|

Art DeKneef Member

|

Good news on the progress. But more importantly, Did you make the car show? |

|||||||||

|

answerman Member

|

Well, *I* made the show, but Ms. Jenavieve didn't. Show was on Friday, and I didn't get done with her till Sunday. Which was too bad, because the local British Sports Car Club was all there, and there were a bunch of MGBs and Midgets, Spitfires, quite a few TRs, and a couple of bugeye Sprites... but no Jensens. I would have been the only one there. I did join the club though and talked with quite a few of the members. We'll be doing other events next year (this was the last one for this year, Wisconsin weather isn't real conducive to this sort of thing between October and April). |

|||||||||

|

answerman Member

|

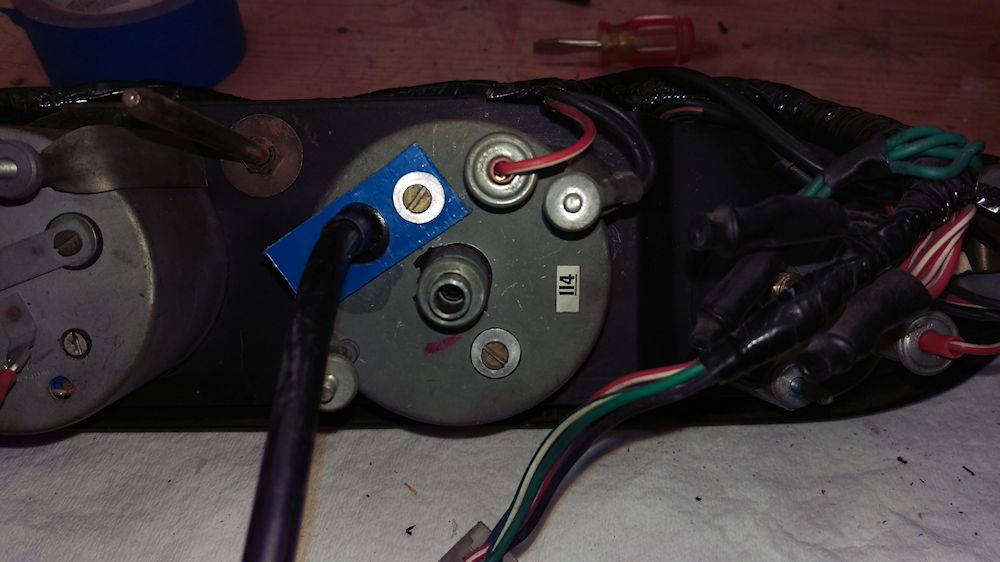

Update. Actually not really an update, because I haven't done much of anything. The weather has been teasing me, being "almost" nice enough outside to drive her, so I've resisted starting any major work that would keep her in pieces for more than a day, but then the weather doesn't get past the "almost" part and she ends up staying in the garage getting dusty. Once in a while I slide into the drivers seat and make a few "vroom vroom" noises. The only thing that's been done to this point was to introduce myself to the Lotus position to pull the tach out to check the wiring. It all seems good, there is 12v where I would expect, etc. and the car definitely won't start with the tach out, so I assume that the wiring is as it should be. But it still doesn't move. At this point I have to assume that the tach itself is bad. Any way to bench test one of these bad boys? Once I'm sure she's off the road for the year, the project will start in earnest. |

|||||||||

|

answerman Member

|

Well, now that we had our first significant snowfall, I expect that Ms. Jenavieve will not be hitting the road until spring. We had nicer weather than I expected this fall and she got about 200 miles put on her just driving around the countryside... otherwise she would probably be farther along. So, the project will be beginning. I'll be starting small things first and then once we get past the holidays I'll have more time to devote. To do list as it stands at the moment, in no particular order: NOW/SOON: Spend a LOT of time with a sander. I want to take her down to bare metal to see just what I have to work with. The overspray that was done by the previous owner just isn't going to cut it, and I'd rather start fresh. Obviously, repair and repaint the body. So far it doesn't look like I'll have too much repairing to do... she's actually in a lot better shape than I initially thought. Replace front brake hoses that I got from Greg about 2 months ago and have been sitting on my workbench. Replace all brake pads/shoes, just because now seems to be a good time to do it. Replace timing belt, just because everyone says it's a good idea. I assume I'll need a new tensioner as well. Find a replacement light switch (I've disassembled mine a couple of times and cleaned the contacts but it's still "intermittent"). Find a replacement tach... I assume mine is bad because I've checked the wiring thoroughly with my Fluke and everything seems to be as it should be. Still, no movement whatsoever on the tach. Fiddle with the carbs to see if I can get her to start any more easily than she does now. A cold start is a 3 minute process these days, messing with the choke and getting her to run for a few seconds, stall, restart, repeat... but once she is warmed up she starts and runs fine. CLOSER TO SPRING: New tires. I'll probably go with close to original (185/70SR13 or so) on the stock wheels. It'll be nice to get a set of tires for what I pay for one tire for my Excursion. The tread is ok on her tires now, but I have no idea how old they are, the sidewalls show a bit of cracking, and for the ~$300 or so it's a good investment. With the amount of driving she'll get, new ones will probably last me 10 years. And, just before spring, a Retrosound radio. Don't need it yet, but it looks at least halfway period authentic for the car(other than the fact that it's digital and has an MP3 port). I just need one that works, and it's got that nice dual knob chrome look. My goal is to have her back on the road all shiny and mostly new by next April. Once I get to that point, I can address the nitpicky points like new dash wood trim, etc. |

|||||||||

|

Art DeKneef Member

|

You made me laugh this morning with your project list. I know you said in no particular order but found it funny you were starting on the small things first and then mentioned spending time with the sander and painting the car. All by April. I hope you have a heated garage. What don't you like about the paint? What kind of paint is it? Single stage or base coat/clear coat? Maybe some fine sanding and polishing will make it better until you have more time for a complete paint job. Taking a car down to bare metal for a respray is a lot of work and time consuming. Especially to do a good job. Voice of experience speaking here. Doing the brake work should be a weekend job. Don't forget the rear brake hose and the rear brake cylinders. Timing belt will probably be the same depending on how much stuff you have to move in order to get the belt off and replace the tensioner bearing. Delta should have replacement light switches. Could it possibly be a weak ground somewhere? Does the distributor still use points or has it been upgraded to a Pertronix? If it has a Pertronix there are reports of the tach not working sometimes. I believe there are a few threads here on the board discussing this. One of the solutions is to have the tach rebuilt with modern components to work with the Pertronix. Do you know when the carbs were last adjusted or rebuilt? Since it seems to occur whenever the car is cold it could be the choke assembly on the front carb needs adjusting, cleaning or rebuilding. Let us know how it goes. |

|||||||||

|

answerman Member

|

Oh yeah, the garage is all ready... got it all insulated and heating installed a couple of months back. I'm good there. Actually I don't think the body work will be that bad. I've done it before... I've got a pretty good setup with a serious air compressor and a good dual action sander. My concern is that I want to only do this once, and I'd rather take the extra time to get the paint right than find out I have rust coming through in a couple of years. There's a bit of bubbling in a few spots and a couple of places where the paint is actually cracked, as though it didn't adhere properly the first time and then raised up. That's the main reason for the repaint. Once I have her prepared to my satisfaction, I have access to a professional paint booth and equipment (the benefit of not burning bridges with previous employers, and she won't be the first car painted in that booth). I haven't decided how far I am going to take the paint as far as the engine compartment etc, but I am planning on removing the hood, trunklid (I should say bonnet and boot, no?) and the doors to at least do them right. Timing belt and brakes are pretty straightforward, as you said. I've not done anything with the rear brakes but as you said I probably should. It's still the stock points ignition. The wiring is all correct from what I've matched to the wiring diagram in the manual and tested with my Fluke. If I take the tach out of the circuit she doesn't run past the first catch so it's definitely in series... in fact I jumpered the two wires together with the tach out and then she started up. I really think it's the tach itself. It's one of those things that doesn't affect how she runs, but it'll bother me till I get it figured out. The light switch is... basically junk. It doesn't stay together (the back falls right off) and it's not making good contact when I push it together. If I tap the switch with my finger when the lights are on I can get them to flicker. I figure a new switch is a small price to pay. I really don't know the status of the carbs... they are Strombergs with the K&N aftermarket filters. Supposedly the previous owner had them rebuilt, but I can't vouch for that, though they do look pretty clean (in fact the whole engine is pretty clean). Like I said, she runs fine once she warms up so I assume it's just adjusting. |

|||||||||

|

Art DeKneef Member

|

Having a heated garage to work in is nice when it's cold. Being from the Chicago area I know how cold it can get there. Having a place to paint is a bonus. Trying to paint in the garage is a pain without the added issues of ventilation and overspray to deal with. What color and type of paint are you planning? My current quick project, which hasn't been as quick as I hoped, is a copper/bronze single stage. Need to spray the engine compartment and hood. The other full restoration car will be base coat/clear coat. When I have done brake work I usually do everything so I know what I have. It may take a little longer and cost a little more, but the thought of everything being checked and fixed is worth it. A new switch sounds to be the answer. The tach will involve a little more work. If an adjustment of the carb's choke assembly doesn't solve the issue then I would think taking it apart and checking would be the next step. I'm rebuilding a set right now and after taking them apart I can see why the car didn't run all that well. They were pretty dirty on the inside. Not that hard just time consuming with all the parts for rebuilding. |

|||||||||

|

answerman Member

|

Well, here's an update. My winter didn't go quite like I expected it to. Crazy cold, too cold for the heat in the garage to compensate, and as a result not much has gotten done. I'm rethinking the whole repaint idea for now, since once it gets nice out I'll be wanting to drive her (other than cracking and bubbling in a couple spots, she looks pretty good from 20 feet away) so I suspect that the body work/paint may wait till after I've finished the mechanicals such as brakes and timing belt. And a set of tires... the sidewalls are pretty cracked on her current set and for what I can get a cheap set of 185SR70/13s for, I'll invest in a temporary set so that I don't have to worry about a blowout. |

|||||||||

|

answerman Member

|

Another victory. Ms. Jenavieve's headlight switch hasn't worked right since I got her. Same problem as outlined by others on the forum. Contacts were pretty burned up inside and the switch would basically fly apart if you looked at it wrong. Intermittent headlights aren't a good option. Anyway, was at True Value Hardware this afternoon, of all places, and they had a black rocker switch exactly the same size and style as the factory headlight switch. It's only a single throw, but since I can't imagine when I would want to have just the parking lights on, I spliced the blue and red wires together so that they all come on when the switch is on. I also bypassed the dash light dimmer, since it has never worked right either. Even at full bright the dash lights aren't exactly what I would call blinding. $10 and an hour's work. Not too shabby for lights that actually work when you flip the switch. One more thing crossed off the rapidly expanding to do list. |

|||||||||

|

answerman Member

|

Baby needs a new pair of shoes! Well, actually two pairs. My Kumho P185/70R13s are in, and will be installed tomorrow. Also ordered the Retrosound Model One radio, which should be here by the end of the week. Between brake hoses and the radio swap, I know what I'm doing this weekend. Spring is in the air and I want to be ready! On that subject, just in case anyone sees this before the weekend... is there a trick to getting to the radio? Can it come out the back of the console, or does the console need to be removed? I didn't see any obvious screws holding it in place other than the two that hold the fresh air vent controls. |

|||||||||

|

Art DeKneef Member

|

You need to remove the center console. Then you will see a couple of screws holding down the radio console to the trans tunnel. Then you look at where the top of the radio console attaches to the dash. On each side there is a small bolt or screw that needs removing also. After removing them you should be able to move the console around and then get the radio out easier. |

|||||||||

|

answerman Member

|

Thanks Art. That's what I suspected. Actually, I need to pull the choke cable out too (the whole cable and housing is trying to move now, pretty sticky in there) so I would like to pull the radio console anyway. Noticed it this morning when I drove her over for her new tires... if I pull the choke knob she chokes right up, but pushing it back in just moves the whole cable so the choke doesn't open back up. Drove over idling at 40mph... lol |

|||||||||

|

Art DeKneef Member

|

The choke cable is a pain to work with. As I mentioned early, did you check the actual choke on the carb? When you disconnect the cable at the carb choke see if the choke assembly moves freely. If not, then it needs cleaning. And you might need a new choke cable if it sticks real bad. But you'll know for sure when you have the cable out. It should slide smoothly. |

|||||||||

|

answerman Member

|

Actually it wasn't that bad. Went to O'Reilly and bought a universal choke kit for $10, pitched everything except the cable housing, and cut it to the proper length. Then I disconnected the cable at the choke (which moves fine by the way), pulled the cable out of the housing, removed the old cable housing all the way back to the dash, and replaced it with the new one. Pushed the old cable back through the housing (after greasing it up good), hooked it back up, and good as new. The problem turned out to be that the housing was pulled off the mounting behind the dash... it was just sliding around with nothing to stop it from moving. The worst part was getting the old mounting point off behind the dash... because I got impatient and didn't wait till this weekend when I was going to have the radio console off anyway, I had to assume the Lotus position and sneak an open end wrench up through to loosen the locknut from the back. Got it though after scraping my knuckles up pretty well. The new mounting is a lot smaller, but still fit fine in the dash opening, though I was ready to put a couple of washers in if needed. |

|||||||||

|

answerman Member

|

Quite the productive weekend. Started off Saturday afternoon *finally* getting around to installing the brake hoses I ordered from Greg last fall, along with the pads for the right caliper (the left side was replaced when I rebuilt the caliper last fall). Like everything else, it all ended up being more involved than I had hoped. First, when I removed the right wheel I immediately saw that something didn't look right. The pads were shifted slightly from their correct position and the top edge was actually riding "off the edge" of the rotor. Looking into it, the lower retaining pin was completely missing! Fortunately, I kept all the extra parts from the Spitfire replacement caliper I bought last fall for the left side (if you remember it didn't fit right but I ended up disassembling it and using the seals and pistons to rebuild the existing caliper) and was able to find a retaining pin there. However, I didn't have the little clips to hold the pins in place... more on that below. While I had the caliper off I decided I might as well clean it up a bit, so I basically did a rebuild of the existing parts. Popped the pistons out using compressed air, pulled the seals, shined up the inside of the cylinders and the pistons with emery cloth, and put it back together. The seals all looked pretty good, which was fortunate since I didn't have replacements handy. The only thing missing at this point were the clips to hold the retaining pins in place ("retainers for retainers?"). The ones I remember from the left side were what I would call "hitch pins" for lack of a better name, kind of shaped like a capital R, with a straight part that fit through the hole in the retaining pin and then curved around to clip against the outside edge. Not sure if these were original, but that was what came with the replacement caliper last fall. Long story short... none of my favorite hardware stores stock such a thing in such a tiny size. What to do? I finally ended up just using a standard (albeit tiny) split cotter pin cut down to about a half inch long, and then carefully bent back around the sides of the retaining pin. It worked fine, but I will be cursing myself when it's time to change the pads again since these are really going to be a bugger to remove again. With the caliper successfully rebuilt and reinstalled, time for the new brake hoses. I only did the front, didn't do the rear one. I'll probably be cursing myself for not ordering all three. Anyway, that went pretty uneventfully. By this time it was pretty late, so I knocked off and picked up Sunday morning after church. With all this done, all that was left was to bleed the system. So, armed with a quart of DOT4 fluid, off we went with Mrs. Answerman on the brake pedal and me on the bleeder valves. After almost a quart of fluid and an hour of getting the three bleed points at least close, we couldn't seem to get all the air out of the system. So, I did a little online research, headed over to Harbor Freight Tools, and came back with a pneumatic bleeder kit (http://www.harborfreight.com/brake-fluid-bleeder-92924.html). Oh wow. I am never going to bleed brakes without this little gem again... best $25 I have spent to date. Took another quart of fluid, but we finally got them bled out properly and the pedal is nice and firm. The rest of the day was preparation for the new Retrosound Model One radio that should be arriving tomorrow. Pulled the door trim panels off, and removed the incredibly crappy speakers that the PO had mounted in the doors... 3 1/2 inch speakers that didn't even fill the opening. No wonder they sounded so rotten. Then, tackled the radio console. Now, this didn't quite go as I expected (actually easier if you can believe that). What ended up happening is that after removing the shifter/e-brake console, I removed the two screws holding the lower edge of the radio console down, and then removed the two screws that hold the vent handles under the dash in place. As Art suggested, there appear to still be screws holding the top edge of the radio console to the dash, but I could not find them for the life of me. Just for fun, I started pulling on the bottom edge of the console and the whole thing wiggled pretty well, but wasn't going to come out. So I pushed it back into position... and the "woodgrain" trim plate popped loose. Ooh! So, I disconnected the choke cable to give me a few inches of give, popped the fan switch off, pulled the bulb assemblies from the 3 warning lights at the bottom, and was able to remove just the panel. Maybe this was the way it was supposed to come out, and I just misunderstood, but regardless I now had access to the front of the radio. The radio was mounted to a plate that was held to the face of the console metal with 4 screws. Took them out and the radio came right out the front of the console. Easy as pie. Again, this may not be the original setup. I will get a couple of pictures of it all before I put it back together. Today's project is to run over to Best Buy and pick up some new speakers to be mounted tonight. I have picked out a pair of JVC 4" coax speakers that look like they will fit into the door space. And, I am going to build a box for the 6 1/2" Alpine rear speakers I will be picking up at the same time. A box that is 34" wide by 7" high by 4" deep should fit nicely in the rear well under the rolled up soft top, covered with cheap automotive carpet. When it's all said and done, I think it will be more a more than acceptable speaker setup for the space available... not audiophile quality, but more than good enough for me. Bonus find of the day was a pair of cabinet doors (one of the neighbors must be remodeling their kitchen) made of 3/4" plywood, 36" high by about 12" wide. Perfect material to make my speaker box, and the price was right. |

|||||||||

|

answerman Member

|

Quick update... picked up the speakers tonight and decided to put them in so that part was done when the radio got here. I have to say I'm confused about the door speaker mounting. They are definitely designed for 4" speakers, since 5 1/4 would overhang the beveled area they mount in, but the 4" speakers I got didn't quite fill the opening. I thought about it for a while and decided to try a little field modification, especially since I didn't care for the way they would have mounted anyway. What I ended up doing was going to the hardware store and picking up a roll of 1/2" sponge rubber window insulation, and circling the back of the door trim cutout for the speaker, so I would have a nice seal between the door trim and the door metal. Then, I put the door trim panel back on and mounted the speaker to the trim panel, drilling holes into the beveled area. That worked out pretty well, though I lost the stock speaker grilles in the process since they wouldn't fit over the speakers anyway. I ended up using the grilles that came with the speakers. Tomorrow: the Retrosound radio arrives, and that goes in along with building and installing the rear speaker box. Once that is all done, the interior will be reassembled and I can actually drive her in comfort (though the weather's not supposed to get out of the 40s for the rest of the week so she'll probably stay in the garage anyway). |

|||||||||

|

answerman Member

|

Radio and speaker installation is complete! As previously mentioned, I found a 4" pair of JVC speakers for the doors and a matching pair of JVC 6 1/2" speakers for the rear deck. The doors:  And the rear well:  What I ended up doing for the rear was to build a box 33" wide by 7 1/2" high by 5" deep, just enough to fit tight into the rear well under the rolled up top and frame. Covered it with cheap black automotive carpet and it looks like it's part of the car. Other than the grilles being very modern looking, it doesn't look too bad if I say so myself. The Retrosound Model One radio installed:  Oh, and the radio is chrome... for some reason I can't get a picture of it without it looking reddish brown. Reflecting off the interior, I suppose. *EDIT* I was able to get a couple of pics in the sun yesterday and the radio and rear speakers pics are updated now. Plus I figured out how to embed pics within the post :-) Anyway, it looks very appropriate in the 1974 dashboard. Last edited on 04-09-2013 12:37 am by answerman |

|||||||||

|

answerman Member

|

Since Joachim updated his project, I guess I should update mine. Decided last night to start hitting Ms. Jenavieve with the grinder. The right side appears to be the worst (from the outside anyway) so that's where I started... So, the rocker is pretty much Swiss Cheese as I suspected. This looks to be a nice straight flat piece, guess I'll just cut it out the entire length right under the groove where the red paint ends, and weld in a new piece of metal.  This will be a bit more of a challenge. I could see that one of the POs had done some Bondo work here. Started chipping away and pulled out all the old school bodywork: about an inch thick of Bondo backed with some wadded up newspaper and rags. Not to mention that when I reached through the hole, the rocker has a nice fill of what appears to be very high quality topsoil, nice and moist. I'll clean that out when I cut the rocker as per the previous picture. Fun stuff. Obviously I'll need to weld some new metal in, but shaping it is going to be interesting. Thinking about doing it as a two piece job, welding a small piece in for the "flange" or "lip" of the wheel well first to connect the flange to the rocker, and then doing the flat piece and mating it to the first one. Last edited on 04-26-2013 09:22 pm by answerman |

|||||||||

|

Art DeKneef Member

|

Fixing the rocker, or is it rockers, is going to be a pain no matter how you look at it. Once you get the rocker opened up and can get a look inside you'll get a good idea if just welding in the flat piece will work. Based on the picture my initial guess would be no. The bottom of the rocker is probably going to be rusted also. And trying to weld on the rusted area will cause more problems. You might think of calling Delta and see if they have rockers and what the cost would be. You might be able to buy 1 rocker and use it to fix both sides. Of course you could always make your own rocker. It's not that difficult. Just requires a lot of bending and measuring. Spoken from experience. The bottom front of the rear passenger fender is another piece you can make. I made one for one of my cars. It takes time and patience to get it right. Well, that and having the right tools really helps also. But this piece is easier to do than the rocker in my opinion. The wheel lip is the hardest part. |

|||||||||

|

answerman Member

|

Talked to Delta today and they will be getting the rockers back in stock shortly, but the repair piece for the rear fender is no longer available (supplier went out of business or something). I think I'm going to go ahead with my original plan of patching the rocker as best I can for now, making a new patch panel for the fender/wheel well (maybe glass and a little Bondo), and doing what I need to to make it presentable for the summer. Then, next winter I can address a permanent solution, probably just replacing both rockers with new ones from Delta as part of the complete stripdown and repaint. For now, I just want to get her on the road and not be embarrassed... the driving season in Wisconsin (which STILL hasn't started) is way too short. |

|||||||||

|

answerman Member

|

Don't shoot me... I know I committed a car restoration faux pas. It's only temporary. I just need it to hold up for the summer and then we'll do it right next winter. Armed with Bondo Glass, Bondo Body Patch, glazing putty, high build primer, and about 9 different grades of sandpaper from 40 to 1200 grit, I've spent the past few days patching up what you saw above. It's not perfect, but it'll pass the 10 foot test. I had my body shop friend match up the paint and get me a quart of single stage with the appropriate reducer and activator, and will cross my fingers that it will match and spray it tomorrow. Pictures then unless it comes out completely bodged. |

|||||||||

|

answerman Member

|

Well, I wouldn't say completely bodged, but the new paint is definitely darker than the old. Giving it a couple more days to harden up and then I'll hit it with the buffer and see if I can blend it a little better. I think it'll be ok for the summer.... at least pass the 20 foot test anyway. |

|||||||||

|

answerman Member

|

Change of plans (as mentioned in another post). I was checking my eBay account to see if the tach I had ordered had shipped (which it had, and I've received it, and it didn't solve my problem, but that's for another post) and ran across a listing for a 1974 JH parts car. Long story short: it now belongs to me and my son and I will be driving over to Perham, MN to pick it up this weekend. From the good side. And....  From the not so good side. As a result of this unexpected event, I am going to hold off on any more body work on Ms. Jenavieve for the summer, and then re-address it next fall/winter when I can do it right with the donor car. I haven't actually seen this in person yet, but according to the owner it's in pretty good rust-free condition (other than the obvious damaged/missing parts). This solves my problem of needing rockers and lower fender repair patches, plus I can use the floorboards and maybe a few other bits. The pictures aren't quite correct as he's since removed all of the exterior lights and trim. And obviously the engine, transmission, interior, dash, etc. are gone as well. Still lots of good parts there, though. The plan is to disassemble this as much as I can this summer and dispose of what I don't need, either by finding people who can use the parts or just storing them "just in case" and sending what's left to the recycle bin. Last edited on 05-14-2013 09:52 pm by answerman |

|||||||||

|

answerman Member

|

Well. JH 19370, or what is left of her, is now in my possession. Nice drive across Wisconsin and Minnesota to pick her up this past weekend. Looking like an excellent investment, the more I delve into her. She belonged to Ernie West (who as I understand is a JHPS member but isn't active on the forum) and we had a really nice chat about JHs in general and ours specifically. Many of the parts from 19370 moved over to his other JH, which was apparently featured in the JHPS newsletter tech talk some time back (before my time apparently). Anyway, got her home and been playing the past couple of days. Like I said above, he stripped pretty much anything that could be unbolted and removed. However, the items I was looking for are all there (along with a couple of nice surprises). The three fenders that weren't damaged in the accident are pretty much perfect, as are the rockers and floor pans. Even the front passenger fender is probably salvageable in the "behind the wheel" area, which is the part I need. Those will all be coming off in the weeks to come. Also (and this made the cost of the car and the transportation much easier to swallow) the soft top, while not perfect, is in perfectly serviceable condition... just needs to be cleaned up. It's a much lighter weight than the aftermarket top that Ms. Jenavieve came with, it's not suffering from any shrinkage (in fact it's a tad loose), and the framework is clean as a whistle. So, the first order of business tonight was to unbolt both top frames and do a bit of regluing at the header rail, and the soft top and frame you see in the picture above is now happily mounted on Ms. Jenavieve. I think it'll be perfectly fine once it's tidied up, and more importantly it actually fits right and I can snap and Velcro the back the way it's supposed to be done. Took all of an hour to swap, and it actually works right. |

|||||||||

|

answerman Member

|

Small update, just because I like to talk about my cars :-) Donor car is getting lighter every day. As of tonight, all 3 1/2 fenders, trunklid, and doors are removed and stored safely in my garage attic until I get to stripping them and prepping for the graft onto Ms. Jenavieve. Also removed and stored in the attic are the stainless door trim from both sides, convertible top frame (actually it's the one from Ms. J), heater, fan, windshield frame, steering wheel, wiper motor, and a few odds and ends like door latch striker plates and the convertible top locating hooks from the rear deck. These all fall into the category of "probably won't use them in the restore, but maybe someone else can use them". To remove yet: rockers/sills and floor pans, which will be part of Ms. J's restore. Once those are removed, all that will be left will be to remove the wheels, front rotors, rear drums, steering column, and rear axle/differential (and the rear taillight surround panel if I can figure out a way to remove it without too much trouble) and then what's left can be carted off to the crusher. Unless someone can think of something I missed that would be of value. I'm thinking that I can have the rotors turned and kept as spare pairs, and the wheels sent off to be blasted and refinished for either spares or swapping if I think they are better than the ones Ms. J has now (both sets are stock style). Meanwhile, Ms. J is all shined up and ready to take part in her first show this weekend... the British Car Field Day in Sussex, WI. Over 200 British cars on display, and from what I've seen in last year's pictures she should be the only JH there (though there were a couple of Interceptors last year). Of course this isn't too far from the Mau family abode, so maybe Ron or Jeremy may be there. We'll be driving down with the local British car club... the lone JH in a procession of MGs, Triumphs, Jaguars, Minis, a couple of Lotuses, and even one Rolls that I know of. I'm not expecting any trophies in her current condition, but it'll be fun just to go take part in it. Last edited on 06-14-2013 06:12 am by answerman |

|||||||||

|

answerman Member

|

It's been a while, though not a whole lot has happened in the interim. Donor car is gone. Got the sills and rockers removed and stored, along with the rear valance (or whatever it's called, the rear panel that the taillights mount into), the rear axle and suspension, and what was left of the front suspension, and called it good enough. What was left was loaded by myself and my two teenage sons onto my little flatbed trailer and carted off to the local recycling center. At 7 cents a pound, this pile of classic British steel resulted in the recycling center handing me $23.80. Kind of sad...  The British Car Field Day was fun. Great weather, over 200 British classics on display. As expected, no trophies for Ms. Jenavieve. Actually, they didn't quite know what to do with her, so they classed her as a big Healey. Take a look at this picture and tell me which car you would vote for... or which one not to vote for. Kind of unfair competition :-)  The remainder of the summer will now be odds and ends that will keep her in driving condition (gotta drive when I can in Wisconsin, the season will be over way too soon) and getting the body panels from the donor car prepped for this winter's transplant. Other than that, probably not too much work on her for a while, though I noticed yesterday that there is a bit of fluid leaking from the area of the right rear brake. It's always something... On the plus side, was vacationing with the inlaws this week in NY state and dropped in to visit Brett Gibson. Had a great couple of hours chatting, sharing tips and getting insights, and looking over his JHs. Last edited on 07-09-2013 08:25 pm by answerman |

|||||||||

|

answerman Member

|

Yup, brake problems indeed. Decided to drive Ms. J to work today for the first time in a couple of weeks, and the pedal is going right to the floor. Looks like it's time to hit the club store for a new rear cylinder (unless I get lucky and it's something silly like a loose fitting... haven't gotten down there to look yet). Sigh. |

|||||||||

|

answerman Member

|

Well, good news for a change. It was in fact the rear right brake cylinder spewing fluid at an alarming rate. However, I was doing some work in the garage and happened to glance over at the rear axle assembly that I removed from my parts car (and was too heavy to drag up to the attic) and lo and behold, the cylinders were still mounted! For some reason I had convinced myself that Ernie had pulled them (like he did the front calipers) before selling me the car, but there they were. Pulled the right rear cylinder, took it apart and cleaned it up just to be safe, and swapped it out with Ms. J's faulty one. After a quick power bleed, I can stop again! This parts car is starting to look like the best investment I've made in a long time. |

|||||||||

|

answerman Member

|

Another puddle on the garage floor. Looks to be gas this time *sigh* It's always something. The boot has always smelled like gas... my guess is with the crazy hot weather we've had the past week, things are expanding and opening a tiny leak into a small leak. Guess I'll be pulling the gas tank for repair... |

|||||||||

|

answerman Member

|

Not much has changed in the past couple months, decided that this was the summer to rip the old wood siding off our house and replace it with vinyl, so that's been taking most of my free time. 3 of the 4 sides (the complicated ones) are done, hoping to finish up the last side over the next couple of weekends. The gas leak I mentioned above seems to come and go... I am writing it off to the weird changes in the weather we had all summer. My guess is there's a tiny leak somewhere in the tank that is expanding and contracting with the weather changes. It'll wait till this winter when the body comes off, and then I can assess the tank for repair or replacement. On a side "fun" note (and I suspect several of you have been there) the first "oh you have a convertible!" moment happened this week. My son volunteered me to drive Ms. J in his high school homecoming parade with a homecoming court couple perched on the boot. So, that'll be fun. Any excuse to show her off, right? |

|||||||||

|

answerman Member

|

Well, it's official. Ms. J is off the road for the winter (it's 31 degrees F which works out to -1 C for those of you across the pond, and likely to get colder rather than warmer for the next several months) which means it's time to start the restoration in earnest. First order of business is to start prepping the panels I took off of the parts car I picked up from Ernie West earlier this year. Fortunately, those appear to still have the original paint so hopefully removal down to either bare metal or a good base shouldn't be too much work. I'll be replacing the front left, rear left, and rear right fenders, the boot lid (maybe, haven't decided yet, depends on whether I want to go with or without the luggage rack she currently has mounted), and the rockers. Looking forward to drilling out all those spot welds fastening the rockers to the inner sills. Since I'm not planning on replacing the sills, I just Sawzalled off the whole rocker and sill assembly from the parts car along with a bit of the floor pan, so those spot welds should be friendlier to drill out (I can just put the whole assembly on my workbench and use my drill press) though the ones on Ms. J will be fun. Is there such a thing as a portable horizontal drill press? Once all that's done, then I get to prep the rest of Ms. J. Lots more fun there. At least one badly done Maaco-style paint job to remove from the bonnet, doors, and other parts not mentioned above. |

|||||||||

|

answerman Member

|

New year, and time to get to it. As I just posted on the Jensen East 2014 thread, I have 19 weeks to get Ms. J ready for the event. Nothing like a deadline, right? I got a bit of a wrench thrown into things when I blew out my knee back in November and had to have it scoped, but I think I'm now ready to tackle the project in full. Assuming the weather warms up some (if you haven't seen the national weather reports, it's crazy here... minus 21 degrees F at the time of this writing) my first goal is to get everything unbolted by this coming weekend. Doors, bonnet, boot lid, and fenders removed, and seats and carpet pulled. Garage is heated and insulated, but that kind of temperature is hard to overcome, so we'll see. Then, it's assessment time regarding floors and rockers, once I have the above stuff out of the way. I took a look at the rockers from the parts car this weekend, and while they are pretty clean as far as rust, they are not exactly perfect (lots of little dings). Still debating if I want to go to all the trouble of using them, or just cut out what I need to cut out on Ms. J and weld in patch panels. Won't know until I can see what I am working with. Wish me luck. |

|||||||||

|

answerman Member

|

The weekend passed and I actually got a lot done! Over Saturday and Sunday, my assistant (the 18 year old son who is anxious to start welding and is planning on this car being his someday) and I made a huge dent (pun not intended) in the disassembly process. First order of business, after removing the battery, was to remove the doors, bonnet, convertible top, boot lid, front bumper, and gas tank. That all went fairly quickly. Then, since I had way more time to work with than I thought I would, off came the headlight pods, headlights, and the left front fender. Not bad for 6 hours of work. I was pleasantly surprised with the condition of the gas tank (my guess is that my leak isn't coming from the tank, but rather from the fittings and/or hoses) and the boot floor itself. Some surface rust, but it seems mostly solid. Sunday, I went back out and decided to tackle her again. Besides removing things like the hooks that hold the top down at the rear, all the snaps that hold the top in place, the taillights, the vertical stainless trim in the door jamb, and the curved trim pieces at the rear of the car, I also removed the left rear fender. Now, THAT was a job. I experienced my first significant rust along the way, and while I was pleased with the condition of the rocker/sill at the front fender (it's actually quite clean) the condition behind the door is pretty atrocious. I was expecting the worst after seeing the bad Bondo job one of the POs had done, and I wasn't disappointed. In order to remove the rear fender, after removing the myriad of bolts and rivets (and having to melt the lead to get at a couple of the rivets), I ended up having to take a Sawzall to the fender in the little section in front of the wheel where it bolts to the rocker since the bolts were covered with about a half inch of Bondo. Once I did that, I was able to wiggle it off. There's basically nothing left to the top of the rocker in the area where the rear fender and the stoneguard attach. After chipping away all the Bondo, the center of it is basically a big hole. Next step will be to get the stainless trim off of the bottom of the door jamb (where it's basically glued to the rocker) so I can assess just how far it's rusted. I remember removing the stainless trim panel from my parts car and it was a hassle... not sure what they used to glue it down but it's seriously strong stuff. That reminds me... they used the same, or something similar, to seal between the top of the rear fender and the edge of the frame where the weatherstrip for the boot lid is. What is that stuff? Some kind of caulk? I found that heating it up only makes it even harder. Anyway, a good weekend of work. Looking forward to next weekend when the other two fenders come off and I can finally assess just how much work we are going to have to put into fabricating metal patch pieces for the rockers. Last edited on 01-14-2014 09:53 pm by answerman |

|||||||||

|

answerman Member

|

By the way, an aside... I thought I'd share an organizational idea I came up with during disassembly. I went and got myself a couple of boxes of Ziploc storage bags, both the quart size and gallon size, a Sharpie, and a pack of index cards. Then, as I remove items, I put them in an appropriate size bag along with an index card stating where they came from. So, as an example, I have a bag with a card labeled "Front Left Fender" which has all the fasteners I removed, along with the side marker light. Another one labeled "Stainless Trim" with the screws from the door trim, the curved trim pieces from the rear of the car, and the little retainer clips for said curved trim pieces. Obviously, the larger parts don't need to be bagged since they are quite apparent as to their identity, but the fasteners that go with them aren't... hence the labeled bags. You get the idea. I would hope that this will aid immensely in the reassembly portion instead of having a box filled with all the nuts and bolts that came from various places in the car all mixed together. |

|||||||||

|

subwoofer Member

|

Pictures, or it didn't happen! :-) PM me if you can't figure out how to attach pictures. -- Joachim |

|||||||||

|

answerman Member

|

Pictures? Oh, I got pictures :-) Tomorrow, I need to get them off my phone. |

|||||||||

|

answerman Member

|

OK, pictures at various stages during the weekend. Here's phase 1, after all the easily removable bits were removed:  And here's where I went farther and took most of the front, and the front fender:  And finally (bad lighting here) the end of the weekend with the rear fender removed.  I'll get some better pictures of the rocker and associate rot a little later, perhaps when I get the other side disassembled. Last edited on 01-14-2014 09:52 pm by answerman |

|||||||||

|

answerman Member

|

Spun Ms. Jenavieve around on her roller skates last weekend to get the fenders off the passenger side. That actually went surprisingly well. Expecting some pretty extensive rust issues at the front of the rear fender/rocker joint, and I wasn't disappointed. The rear fender was basically just Bondo'd to the sill. The "tab" at the bottom of the fender wasn't even there. As promised, closeups of the rocker/sill calamity:  Ummm... the top of the rocker is pretty much gone! Also, the door jamb is pretty much gone in the bottom area.  Another view of the same area. Haven't hit it with the grinder yet, but there's not much to work with there.  At least the front is mostly in once piece. Obviously, there are likely rust issues on the inside that I can't see at this point, too. Debating whether to just cut out and weld sheet metal as needed, or perhaps chopping up the rockers I took off my parts car to patch in the front and rear bad spots, while leaving the middle (though I know I need to cut out a "window" and weld in new metal in the center under the door). The fewer spot welds I have to drill out, the better. And of course fabricate a patch piece for the bottom of the door jamb. This is getting fun! Last edited on 01-22-2014 08:12 pm by answerman |

|||||||||

|

answerman Member

|

Rant time. We were looking at the passenger side rocker/sill from different viewpoints, and decided that since it's in pretty good shape (other than the obvious spot behind the door) the most straightforward route would be to chop the rocker I took from my parts car a few inches into the door opening and weld it in to replace the existing rotten area (basically making the rearmost 12 inches or so new from about the drain hole in the door jamb back to the wheel cutout). After fighting with it for the better part of yesterday and today, it's just not worth it. After drilling out about 30 spot welds, I still don't have the outer panel separated from the rest of the sill on the piece I want to put in. Not to mention that I haven't even started trying to remove the associated parts from the car. The rear corner of the rocker/sill is the wackiest welding job I have ever seen. Counting the outside (visible) panel, the inside stiffener, the end triangular piece that closes it off, and the inner sill, there are 4 (yes 4) layers of metal that are welded together at the rear. Going to take a day to lick my wounds (and wait for it to warm up a bit, supposed to hit -25 degrees F tonight) and then look at it again and see just how hard it would be to fabricate a new piece or pieces to patch what needs to be patched. I'm trying very hard to do this all "right" but I keep losing sight of the fact that most of this repair will not even be visible when the fender is re-mounted. So, the plan at this point is to make a couple of new pieces to fill in the big hole, welding to the inner unibody panel and then wrapping over to meet the rocker at the point where it changes from red to black in the picture above. Then, patching the bad spot behind the front wheel, cutting out most of the visible flat part of the rocker under the door and welding in a new flat piece of metal. At least this is the bad side. The drivers' side is in much better shape... really the only bad spot is behind the door and it's not half as bad as the passenger side. I'll get past this, but just frustrated right now. Last edited on 01-28-2014 05:34 am by answerman |

|||||||||

|

Art DeKneef Member

|

Oh, I so understand the frustrated part. You're correct with the funky metal layers and removing the rusted metal. But it can be done. First thing I would do is remove all the paint, tar, sealer, etc. from the areas and get down to bare metal to actually see what you are working with. And I would start with the front to hone my skills so to speak before working on that rear section. Those rear pieces aren't that difficult to make with basic hand tools, just time consuming. If you need some pictures of those areas let me know. I have another car under restoration that is apart in those areas if you need some pictures. |

|||||||||

|

answerman Member

|

Thanks Art. I just needed to vent a little because I thought my original plan was going to work better than it did. I didn't expect that it was going to be such a hassle to remove the outer rocker from the assembly from the parts car, and I feel like I wasted an entire weekend. Definitely going with plan B... clean up all the paint and tar and such to see what's salvageable on the car, de-rust as best I can, and cut out the nonsalvageable stuff and weld in new. As long as it's structurally sound, that's all I'm worried about... like I said 98% of this repair won't even be visible when the car is reassembled. |

|||||||||

|

answerman Member

|

Just an update, or lack thereof. The past few weeks have been kind of busy so not a whole lot getting done on Ms. J. When I've had a spare hour or two, I go out to the garage and pick a part to strip the paint off of. Lots of cleanup to do from things like the headlight rings and trim having overspray from the PO's bad paint job. Things get much calmer after this coming weekend, and then I will start having more progress to report. January kind of got away from me, so I need to get my nose back to the grindstone. The Jensen East meet is coming sooner than I would like... gotta be ready! Last edited on 02-17-2014 09:00 pm by answerman |

|||||||||

|

answerman Member

|

Good news for a change. Took Art's advice and spent some time cleaning up the chunk of rocker/sill that I chopped off my parts car. Got it pretty much down to bare metal, and it became much clearer how everything was welded together. I swear those Jensen welders must have gotten paid by the spot weld... Anyway, once I was able to see what was holding everything together, I was able to drill out the welds I needed to in order to separate the outer rocker from the rest of the sill. Then, I moved on to Ms. Jenavieve and did the same. I figure about an hour of final cleanup this weekend, and then I will be ready to graft the nice new piece of outer rocker into place. That will be a huge load off my mind. Feeling much better about the project now. |

|||||||||

|

answerman Member

|

Another mostly productive weekend went by, with only one calamitous discovery (which I was kind of expecting anyway). First, the good. Yesterday, we finished the graft of the "new" section of rocker panel to Ms. Jenavieve. Came out pretty good. Apparently two semesters of welding classes have made an impact on my 18 year old. Ground down the seam and with a little filler you won't even see the seam. Also spent a LOT of time with a sander/grinder this weekend. All paint is removed, down to bare metal, on the rear valance, the rear deck (between the convertible top well and the trunk opening) and both rockers and door jambs. All that's left to do of the "unibody" is to finish paint removal and prep of the trunk interior and the engine compartment. Then, prime and paint. I'm taking a week off from work (it's nice to be self employed) next week to spend several full days working on her. The goal is to have this work all done by the 15th of March. Now, while I was doing all this, I also stepped to the side and started the paint removal of the hood, because I had a nagging feeling that all wasn't well there. Of course, I was right. Armed with a 50 grit sandpaper disc and backing pad on my angle grinder, I went to work. After I got through the Maaco paint job layers down to the original finish, I started running into body filler. Yup, someone creased the hood at some point. They did a pretty good job with the filler, it wasn't even noticeable other than the paint had cracked over it (which was my clue, it was right over the area where the telescoping hood strut would have been if it was still installed). Of course, I didn't discover it until AFTER I hit it with the sanding wheel, so the filler got gouged up pretty bad. I ended up just going down to the bare metal there as well, and can see all the peen marks and such where they bashed it back into shape. No more than 1/8" of filler, but that's enough, and though I'm pretty fair with body filler this looks like a bit of a challenge with all the contours of the hood. I may ring up my body shop friend and see what he'd charge me to do it right. Anyway, still not ahead of schedule, but at least not behind. |

|||||||||

|

redracer Member

|

answerman: there is a very nice fix for "the bend" in the hood caused by someone inadvertantly trying to close it without lifting up the release catch first.(I saw this first on Clay Gleason's J-H--he called it "LUCIE", Seattle, WA.) I have fixxed one myself, even though I am not a "body" man. If interested, call 404-261-2552 or SKYPE "RockClimber52" me. |

|||||||||

|

answerman Member

|

Talked to my body shop friend and he thinks he can get the hood properly filled and shaped for about $100. Going to take him up on it, since I'd probably spend half of that just getting the proper supplies and tools, and no guarantee it would be done right. This looks best left to the pros. |

|||||||||

|

answerman Member

|

Well, today was productive, though some unplanned time got added to the project. I thought I was close to priming and painting the "concealed" parts of the unibody (engine compartment, door jambs, etc). All prepped (or so I thought) and masked... bare metal on some, and sanded and scuffed on the rest. So, I spent an hour at the auto paint store, and got a lot of free advice as part of the deal (remember I am hardly a professional at this restoration stuff and the last time I did it was 25 years ago). Long story short... something I didn't even think about. He basically explained the different kinds of paint to me and told me that the 2k urethane primer I was going to use would likely lift the old lacquer finish right off the car. Oh boy. Not what I wanted to hear. The whole reason for the repaint is to get rid of the Maaco bubbles! So, the project has altered slightly now: she will be a true bare metal restoration. Hadn't planned on it all the way through (I'm doing the "visible" panels such as doors, fenders, etc. because I have to remove the horrible Macco paint job) but now it ALL has to come off. Including the parts from the parts car. Not horrible, but time consuming. I got most of the engine compartment done tonight, will finish tomorrow after I get a new drill (burned up my 25 year old Black and Decker tonight) and hope to finish it tomorrow. What seems to be working well is to use a pretty aggressive chemical stripper (Zinsser StripFast), let that sit for a half hour, scrape off most of the old finish (it doesn't seem to have any trouble going through most of the layers) and then hit what's left with a 3M SandBlaster disc on my drill or grinder, depending on the angle I need to hit it at. It's always something... but in retrospect it's probably a good thing since it's forcing the engine compartment to be cleaned really well. I'm doing this with the engine still in the car, using aluminum foil to mask off anything I don't want painted. The Zinsser stripper, in addition to removing the paint, also does a fine job of removing most of the possibly 40 years worth of grease buildup. We'll see how it goes. |

|||||||||

|

Art DeKneef Member

|

What paint/primer exactly were you planning to use? A paint product with hardener will cause problems like that. You could have used a sealer to cover the old paint and then applied your regular paint over that. I'm having a hard time visually with you painting the engine bay with the engine in it though. |

|||||||||

|

answerman Member

|

Yes, it's a 2K PPG urethane primer, and the topcoat will be a PPG single stage urethane paint with activator. Most of the old paint had to come off anyway since it was such a badly done overspray, but I hadn't planned on all of it. Oh well. It's off now, at least on the unibody, and it's probably the right way to do it, right? Primed today, will be topcoating tomorrow (got it up to a nice 82 degrees in my garage). And yes, the engine is still in place. Basically what I did was to Reynolds Wrap anything I didn't want painted. Works better than paper and tape, just mash it around whatever you're masking. The complete engine bay won't be painted, just down to and including the structural channels about halfway down. I think it'll be ok... not going for show quality, just an improvement (a DPO apparently decided it was a good idea to spray part of the engine compartment black at some point and about half of it peeled or just wore off). I'll post before/during/after pics when I'm done. Once all this is done, I can tackle the fenders, doors, and boot/trunk lid, all of which have been removed for some time and will be much easier to work with. The bonnet/hood is already stripped. Last edited on 03-14-2014 08:41 am by answerman |

|||||||||

|

Jensen Healey Super Moderator

|

Just a note on toxicity of 2k paints. http://www.sigmaaldrich.com/analytical-chromatography/air-monitoring/applications/paints-and-coatings/binding-agents.html You need to consider harm to yourself and others. |

|||||||||

|

Art DeKneef Member

|

Removing the old paint is the best way to go. You remove all the variables that might arrive from going over old and different paint. That's what I did for my major restoration project. Your garage temp was our outside temp today. And now I can picture what you are doing to the engine bay. Makes sense. Then the fun really starts when you do all the other pieces. Oh yes, I agree with the toxicity of today's paint. The best way to spray is with a fresh air hood and good ventilation. Even with the waterborne base coats, the clear still has ISOs in it. |

|||||||||

|

Randallclary@icloud.com Member

|

Has anyone used Kleen Strip Aircraft Paint Remover? It was recommended to me by World Class Restoration out of Riverside, CA. I read posted reviews, not from the JH Forum and they looked pretty good. My 13046 has both the original factory yellow and black when the car was last painted back in the late 90's. I am doing a to bare metal restoration and a 2.2 Stroker Crank upgrade with the 104 and 107 cams with the 45 mm Delloroto Carbs. Called the money pit. Maybe that will be the name of the car. |

|||||||||

|

Brett Gibson JH5 20497 Member

|

Yes I used it, painted it on with a brush placed plastic wrap over the top and let it sit for 5 to 10 minutes then just used a scrapper to peel off one layer after another, the plastic wrap helps to keep the solvent from evaporating to quickly. Good quality product. Brett |

|||||||||

|

answerman Member

|

Pics if anyone's been wondering what I've been doing. I'm calling the unibody done at this point, fenders and bonnet/hood are all stripped and ready to paint (once I repair a little Bondo work I unexpectedly ran across on one of the front fenders). Then, all that's left is trunk/boot lid (should be simple) and doors (will probably be a pain). Against the advice of several here, I did decide to paint her in stages and then reassemble the already painted panels. Planning on being uber careful when remounting everything, and if I scratch things up it's my own damn fault (though I have to say that the urethane finish dries like a rock, not easy to scratch). A couple of "before" shots:  The engine bay, showing the deteriorated condition of the original paint plus what's left of what appears to be a quick black overspray with Krylon. I've got things masked off with Reynolds Wrap, ended up taking it all off to redo after I stripped the paint (more on that below)     The rear valance and taillight surround with most of the old paint removed... And then I proceeded to strip the engine bay.  This was an adventure. Stripping wheels on the grinder and drill, and a tiny little flap wheel on my Dremel extension for those hard to reach places. Remasked with foil and ready to spray. And finally, after 3 coats of PPG 2K urethane primer, followed by 4 coats of PPG Cardinal Red single stage urethane...   Quite a difference. This was my first time working with this type of paint. I have to say it goes on nicely, easy to work with, and cures to a rock hard finish. Of course, having the garage heated up to 92 degrees for 48 hours aids the process. These bad boys are next up, stripped and mostly ready.  I still need to do the Bondo work on the bonnet/hood and one of the fenders just under the headlight pod cutout. That should be done tonight, and the plan is to get them primed and painted before the weekend if all goes well. Last edited on 03-18-2014 09:05 pm by answerman |

|||||||||

|

answerman Member

|

A reasonably productive weekend. Friday, decided that since I'm done with the chassis for now until I get the fenders, etc. painted, I decided to take Ms. J over to the 10x20 storage unit I'm renting. This will make the garage much easier to get around in for painting the assorted panels, and I don't have to worry so much about overspray hitting her. As I thought about it, I realized that the only thing keeping her from being "drivable" was that her battery and fuel tank were removed (and in the storage unit with the other bits removed from her). So, went over there (it's only about a block from the house) and grabbed both those bits, brought them back, and charged the battery for about a half hour while my son and I put the fuel tank back in, at least temporarily. Was more than pleased that she started more or less right up (she's never been what I would start an easy starter), so the only thing keeping me from driving her over to the storage unit was the "legality" of it. Was that going to stop me? No, of course not. So, with Mrs. Answerman tailgating me with her 4-ways on, I drove her over in the condition you see above. No doors, fenders, bonnet, or boot lid. Got a few funny looks but it went pretty uneventfully. Then, I spent the rest of the night doing the Bondo work I needed to do on the bonnet, as well as one of the fenders (unearthed a repair when I was stripping her paint off, and of course I wrecked the existing Bondo in that process). That went fine and they are ready to prime and paint. I think I am going to strip and prep the boot lid and the doors beforehand though, so that I can paint everything needing to be painted at once. One thing came up during all of this, which initially was an "oh crap" moment but actually turned out ok, was that it was easy to see where my fuel leak in the boot is (with everything being removed and cleaned up}... it's definitely a leak in the bottom of the tank. Well, at least now I know what it is. So, I called on a local radiator shop on Saturday morning and it turns out they can do a complete recondition on the tank (chemically clean, weld/solder anything needing to be repaired, and then coating the inside) for somewhere between $100 and $150, depending on how much repair needs to be done. Not a bad price considering the alternative of sending Jorge $400 for a tank that may not even go in right. I can live with it. So, the tank will go off to the shop tomorrow and be reconditioned while I'm doing the rest of the painting. About a month ahead of schedule at this point. Getting excited for spring to get here! |

|||||||||

|

answerman Member

|

More painting today. Primed and painted the fenders and headlight "sugar scoops", and primed the hood/bonnet and trunk/boot lid. I'll be painting those tomorrow, didn't have enough room in the garage to hang everything properly and while I had the fenders on sawhorses to prime them, it's a heck of a lot easier to paint them if they are hanging. At least that's my experience. So, at this time tomorrow, all that should be left to refinish is the doors, which I haven't even started yet. Those look like they will be a gigglefest to disassemble. |

|||||||||

|

answerman Member

|